13 Recycling Myths You May Not Have Known

- Biznex SEO

- Sep 23

- 5 min read

Introduction

In the rapidly growing world of e-waste and metal recovery, many start-ups and

businesses aim to adopt eco-friendly practices. Yet, recycling myths abound from

exaggerated success stories to oversimplified claims about machines and metal recovery.

These myths can mislead businesses, slow adoption, or create unrealistic expectations.

For instance, tales of Olympic gold medals made from recycled electronics or claims of

100% metal recovery often inspires aspiring entrepreneurs but rarely reflects practical

reality. According to a study conducted by ResposeIndia, India alone generated 1.751

million tones of e-waste in 2024, and most start-ups are unaware of the actual

challenges in processing it efficiently. Understanding these recycling myths is crucial for

informed decision-making and building sustainable recycling operations.

Myth 1: Recycling is 100% efficient and nothing goes to waste

Many people believe that recycling machines can magically extract 100% of metals and

materials from e-waste. This is one of the most common recycling myths in the

industry.

Reality: Even the most advanced fully automatic PCB recycling machines cannot

recover every single particle. Factors such as waste type, machine design, and post-

processing impact efficiency. A recovery rate of 95–97% is excellent, but expecting

perfect recovery is unrealistic.

Myth 2: Small recyclers can easily compete with large plants

Start-ups often assume that purchasing a small machine immediately positions them to

compete with large recycling plants. This misconception is another widespread recycling

myth.

Reality: Small semi-automatic PCB recycling machines are suitable for pilot projects or

niche operations. Large-scale facilities have higher throughput, automation, and

regulatory compliance. Believing that a small setup can match industrial operations can

lead to frustration and financial loss. Small setups need to adopt a strategic approach for

success. ResposeIndia specializes in helping such small setups succeed.

Myth 3: Recycled metals are always as good as virgin metals

It is a common recycling myth that recycled metals have the same purity as newly mined

metals.

Reality: While recycled metals are valuable, recovery processes can leave minor

impurities which need to be removed later through refining. Nonetheless, recycled metals

significantly reduce environmental impact and material costs for most applications. Also,

most applications of metals involve adding certain impurities to achieve the desired

properties.

Myth 4: Olympic medals prove e-waste recycling is easy

Stories like the Tokyo 2020 Olympics claiming medals were made from recycled

electronics often inspire start-ups, but also spread a misleading recycling myth that it is

very easy.

Reality: This project involved two years of collection drives and industrial-scale

processing. Besides, Japan’s nationalist culture helped when people actually donated

brand new electronics for the Olympic cause. It’s symbolic and cannot be directly

replicated as a business model. Understanding this prevents unrealistic expectations in e-

waste ventures.

Myth 5: Recycling is always profitable from day one

Many believe that e-waste recycling is a quick way to make money, a persistent

recycling myth.

Reality: Initial investments, compliance, operational costs, and logistics are significant.

Profitability depends on scale, scope, technology adoption, and consistent supply.

Responsible recyclers focus on long-term gains rather than instant profits.

Myth 6: All e-waste is the same

A common recycling myth is that e-waste can be treated uniformly.

Reality: E-waste ranges from laptops and mobile phones to refrigerators and industrial

PCBs. Each requires specialized machinery and processes, especially during the

preprocessing. Further depending on the contents of the electronics, the downstream

metal recovery processes may need to be modified. Using a single method for all types of

e-waste leads to inefficiency and material loss or simply may not be possible.

Myth 7: Anyone can start a recycling business without expertise

Believing that buying a machine is enough to start an e-waste business is a critical

recycling myth.

Reality: Expertise is needed for handling hazardous materials, regulatory compliance,

and machine operation. Partnering with experienced providers like ResposeIndia ensures

safe and profitable operations.

Myth 8: Recycled products have no market value

Many think that recovered metals and plastics have limited demand, a misleading

recycling myth.

Reality: Markets for secondary raw materials are growing. Quality and consistency are

crucial, and materials processed via professional machines fetch good prices.

Myth 9: E-waste recycling is just about metal recovery

Some assume that e-waste recycling only focuses on metals. This is another recycling

myth.

Reality: Modern recycling recovers plastics, glass, and composites. Ignoring non-metal

materials increases waste and environmental hazards. Efficient recycling processes

maximize recovery across all material types.

Myth 10: Informal recyclers are as good as formal recyclers

A widespread recycling myth is that informal e-waste handling is sufficient.

Reality: Informal methods like acid baths or open burning are dangerous and polluting.

Formal recycling facilities follow strict standards, ensuring safety and sustainability, as

highlighted by Respose India’s studies.

Myth 11: Advanced machines don’t need skilled operators

It’s a recycling myth that machines run themselves.

Reality: Skilled operators are essential for efficiency, maintenance, and compliance.

Automation reduces manual effort but cannot replace expertise in recycling processes.

Myth 12: India’s recycling infrastructure is already sufficient

Some believe India’s e-waste ecosystem is fully capable of a common recycling myth.

Reality: Less than 20% of India’s e-waste is formally recycled. There’s an urgent need

for scalable technology, proper collection, and trained operators. Awareness of these gaps

helps start-ups plan realistically.

Myth 13: Recycling alone can solve the e-waste problem

Finally, the belief that recycling itself will solve e-waste challenges is one of the most

persistent recycling myths.

Reality: Recycling is vital but not a standalone solution. Product design, responsible

consumption, collection systems, repairs and refurbishing, EPR schemes,

government SOPs are equally important. Only an integrated approach ensures a circular

economy.

The Reality behind Recycling Myths

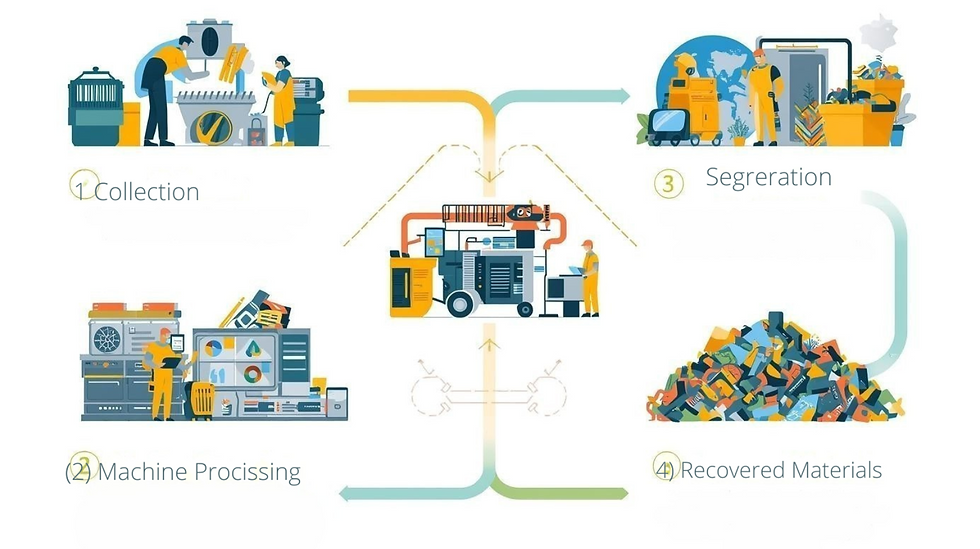

Understanding the difference between hype and reality is essential for start-ups and

businesses. E-waste recycling is a technical, regulated, and multi-step process.

Advanced PCB recycling machines and professional recovery facilities ensure that

valuable metals are reclaimed efficiently and safely.

For a deep dive into India’s actual recycling scenario, check out:

FAQs on Recycling Myths

Q1. What are the recycling myths start-ups should avoid?

Believing informal methods are sufficient, assuming 100% recovery, or thinking small

machines can compete with large plants are common misconceptions.

Q2. Are e-waste recycling machines profitable?

Yes, with proper scale, compliance, and trained operators. Long-term strategy is key.

Q3. Can recycled metals match virgin metals?

Mostly yes for general applications, but some high-precision uses may still require virgin

metals.

Q4. Is recycling alone enough to manage e-waste in India?

No. Recycling must be combined with responsible collection, repairs, refurbishing, and

regulatory compliance.

Q5. How can businesses safely handle data on e-waste devices?

Certified recyclers provide secure data destruction, including HDD shredding and

industrial data erasure, as part of their services.

Conclusion

Busting these 13 recycling myths highlights that e-waste recycling is both impactful

and challenging. Start-ups and businesses must understand the limits of machines, the

nuances of metal recovery, and the importance of formal processes.

By working with experts like ResposeIndia, leveraging fully automatic PCB recycling

machines, and adopting best practices, businesses can turn waste into opportunity

Comments